Productscpzx

PEEK

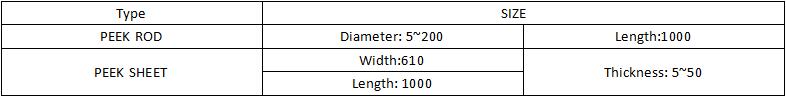

Product Type

Peek rod,PEEK sheet,PEEK tube ect.

Main Properties & Application

-High mechanical Strength (機械強度高)

-Good thermal Stability (良好的穩定性)

-Excellent dimensional stability (優異的尺寸穩定性)

-Optimised balance of stiffness,tensile strength and impact strength (產品剛度、拉伸強度和沖擊強度優良平衡)

-Good machine ability(良好的機械加工性)

-Continuous working in high temperature(高溫下持續工作)

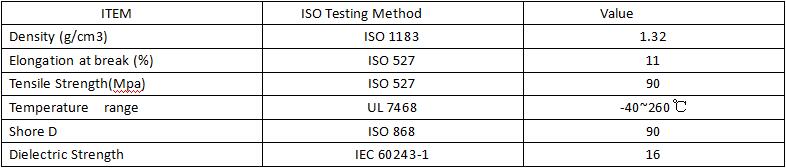

Technical Specification

Introduction to PEEK Sheets

PEEK sheets are high-performance engineering plastic sheets made from Polyetheretherketone (PEEK) resin through extrusion or compression molding processes. They represent the top tier of performance among thermoplastic materials, renowned for their exceptional high-temperature resistance, mechanical strength, and chemical stability, making them ideal for the most demanding applications in aerospace, medical, and semiconductor industries.

Core Characteristics

PEEK sheets exhibit extraordinary properties that set them apart from other plastics:

| Characteristic | Description | Advantages |

| Exceptional High-Temperature Resistance | Continuous service temperature up to 260°C, with short-term exposure possible to 300°C. Glass transition temperature at 143°C, melting point at 343°C. | Maintains mechanical properties at elevated temperatures where most plastics would fail. |

| Outstanding Mechanical Properties | Highest strength and stiffness among thermoplastics, with excellent fatigue and creep resistance even at high temperatures. | Can replace metals in structural applications while providing weight reduction. |

| Superior Chemical Resistance | Resistant to virtually all organic and inorganic chemicals except concentrated sulfuric acid and halogenated solvents. | Performs reliably in aggressive chemical environments where metals would corrode. |

| Excellent Wear & Abrasion Resistance | Low friction coefficient and outstanding resistance to dynamic wear, comparable to many specialty alloys. | Ideal for high-load bearing applications without lubrication. |

| Inherent Flame Retardancy | UL94 V-0 rated without any additives, with very low smoke and toxic gas emission. | Meets stringent fire safety requirements in aerospace and transportation. |

| Radiation Resistance | Exceptional resistance to gamma and X-ray radiation. | Suitable for medical and nuclear applications where radiation sterilization is required. |

Limitations:

· High Cost: Significantly more expensive than other engineering plastics (typically 5-10 times the cost of PTFE or nylon).

· Processing Difficulty: Requires very high processing temperatures (380-400°C) and specialized equipment.

· Hydrolysis Resistance: Although generally excellent, prolonged exposure to superheated steam above 130°C can cause degradation.

Common Grades

PEEK sheets are available in several grades to meet specific application requirements:

| Grade Type | Key Features | Typical Applications |

| Unfilled PEEK | Optimal combination of strength, toughness, and chemical resistance. | General high-performance applications, chemical processing equipment. |

| 30% Glass-Filled PEEK | Enhanced stiffness, strength, and dimensional stability. Reduced thermal expansion. | Structural components requiring high rigidity and close tolerances. |

| 30% Carbon-Filled PEEK | Highest strength and stiffness, superior wear resistance, and electrical conductivity. | High-wear applications, static-control components, semiconductor manufacturing. |

| Carbon Fiber Reinforced | Exceptional strength-to-weight ratio, very low creep, and excellent fatigue resistance. | Aerospace components, high-performance automotive parts. |

| Wear-Resistant Grades | Modified with additional lubricants (PTFE, graphite) for ultra-low friction. | Bearings, seals, and components requiring dry-running capability. |

Performance Data Table

| Parameter | Unfilled PEEK | 30% Glass-Filled | 30% Carbon-Filled | Test Method |

| Tensile Strength | 100 MPa | 165 MPa | 215 MPa | ASTM D638 |

| Flexural Modulus | 3.8 GPa | 10.5 GPa | 15.0 GPa | ASTM D790 |

| Continuous Service Temp. | 260°C | 260°C | 260°C | - |

| Coefficient of Friction | 0.35 | 0.30 | 0.25 | ASTM D1894 |

| Water Absorption | 0.5% | 0.4% | 0.3% | ASTM D570 |

Typical Applications

1. Aerospace: Structural components, bearing retainers, electrical connectors, and interior components requiring low smoke and toxicity.

2. Medical: Surgical instruments, orthopedic implants, dental components, and sterilization trays (reusable after autoclaving).

3. Semiconductor: Wafer carriers, chemical mechanical polishing components, cleanroom equipment, and vacuum handling tools.

4. Oil & Gas: Seals, bearings, and downhole components resistant to harsh chemicals and high temperatures.

5. Automotive: Transmission components, engine parts, and sensors for high-temperature underhood applications.

6. Food Processing: Equipment components requiring repeated steam sterilization and FDA compliance.

Machining & Processing

· Machinability: PEEK machines similarly to brass, producing clean chips rather than continuous strings. Requires sharp tools and adequate cooling.

· Drying: Must be thoroughly dried before processing (2-3 hours at 150°C) to prevent surface defects.

· Annealing: Recommended for stress-relief after machining, especially for precision components (typically at 20°C above intended service temperature).

PEEK sheets represent the pinnacle of high-performance thermoplastics, offering a unique combination of properties unmatched by any other plastic material. While their high cost limits them to the most demanding applications, their ability to perform in extreme environments—where metals would fail or corrode—makes them indispensable in advanced technological sectors. From medical implants that withstand repeated sterilization to aerospace components that maintain integrity at high altitudes, PEEK sheets continue to enable innovation across industries where failure is not an option.