Productscpzx

Introduction to Black PE Sheets

Black PE sheets are panels primarily made from polyethylene (PE) with the addition of carbon black pigments and UV inhibitors, produced through extrusion or calendering processes. Depending on density, they are mainly classified into High-Density Polyethylene (HDPE) sheets and Low-Density Polyethylene (LDPE) sheets.

Core Characteristics

| Characteristic | Description | Advantages |

| Excellent Chemical Resistance | Highly resistant to chemicals such as acids, alkalis, and salts. | Suitable for corrosive environments like chemical containers and electroplating tanks. |

| Good Impact Resistance | Particularly HDPE sheets offer high impact strength. | Ideal for manufacturing parts requiring impact resistance, such as storage boxes and transport containers. |

| Low Friction Coefficient | Smooth surface with low friction coefficient. | Suitable for slides, liners, and other low-friction components. |

| Strong Weather Resistance | Enhanced with carbon black and UV inhibitors, offering excellent anti-aging properties. | Suitable for outdoor use with a service life of 5-10 years. |

| Non-Toxic and Odorless | Complies with food safety standards. | Applicable in food processing and packaging industries |

Main Types and Specifications

Type Density (g/cm3) Characteristics Applications

HDPE Sheets 0.941-0.965 High hardness, good mechanical strength, better temperature resistance. Chemical equipment, mechanical parts, load-bearing structures.

LDPE Sheets 0.910-0.925 Good flexibility, high impact resistance, easy to process. Packaging materials, cushioning materials, shock-absorbing liners.

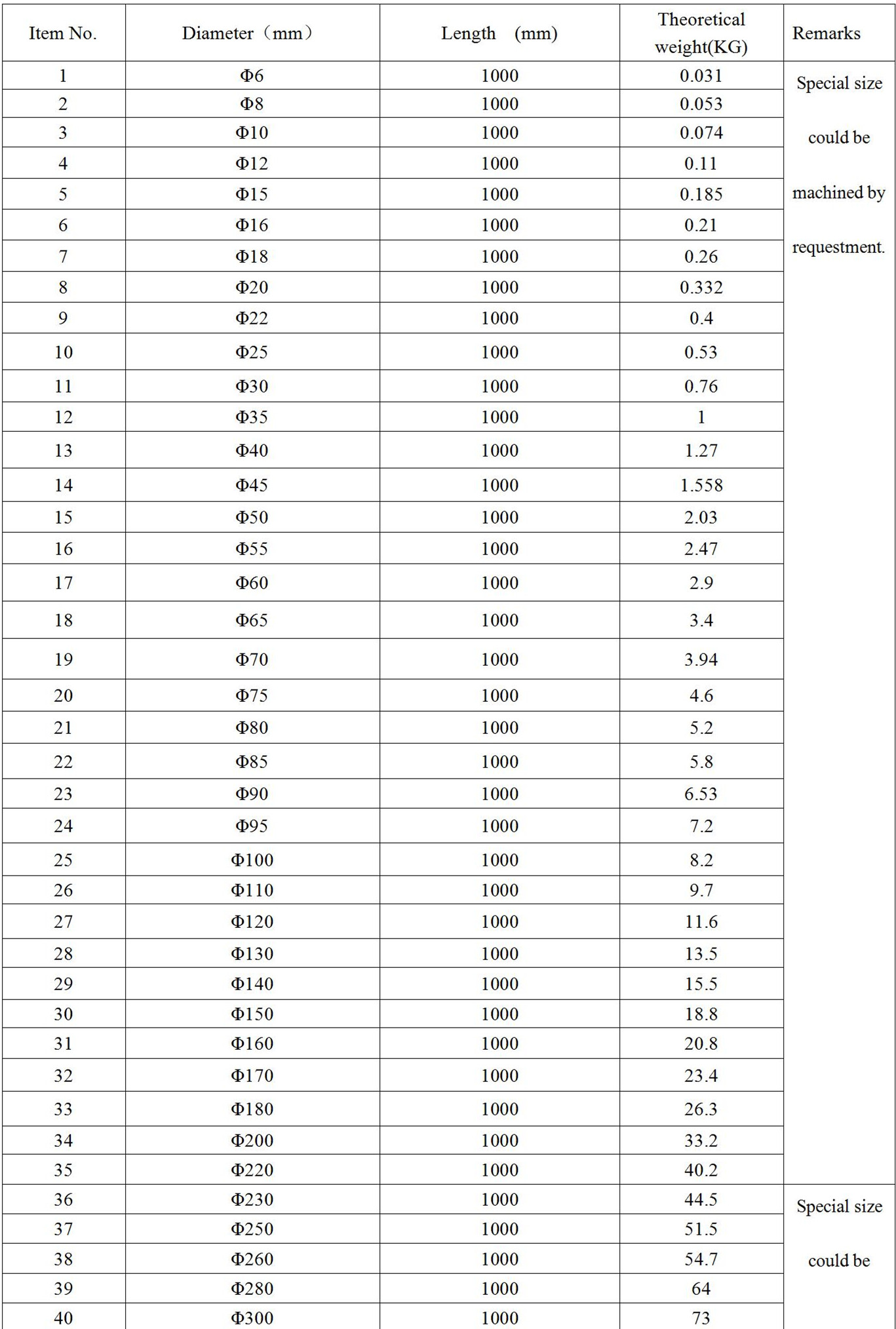

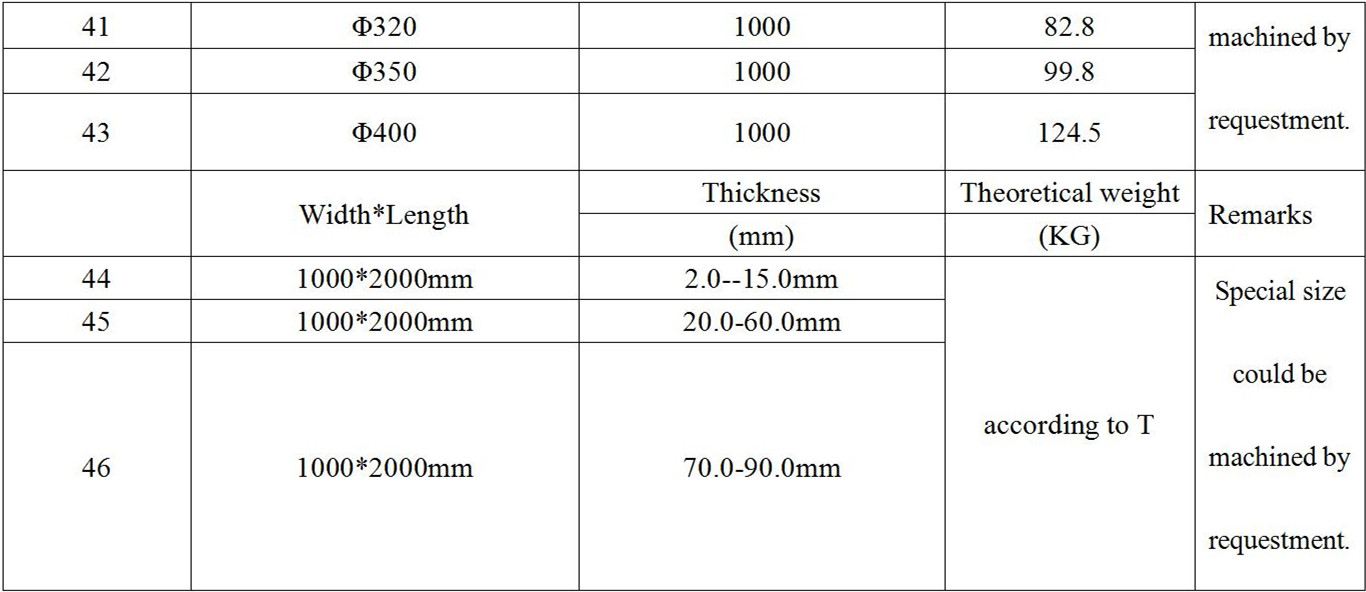

Common Specifications:

· Thickness: 1-100 mm

· Dimensions: 1000×2000 mm, 1220×2440 mm, etc.

· Color: Black (other colors can be customized as needed).

Perforance Parameters Table

Performance Indicator HDPE Sheets LDPE Sheets Test Standard

Tensile Strength (MPa) 22-31 8-16 ASTM D638

Flexural Strength (MPa) 20-28 5-10 ASTM D790

Impact Strength (kJ/m2) No break No break ASTM D256

Operating Temperature (°C) -50 to +70 -50 to +60 -

Thermal Conductivity (W/m·K) 0.44-0.51 0.33-0.38 ASTM C177

Application Fields

1. Chemical Industry: Electroplating tanks, pickling tanks, chemical container linings.

2. Logistics and Transportation: Pallets, transport boxes, cargo liners.

3. Food Processing: Cutting boards, work surfaces, food containers.

4. Construction Industry: Basement moisture-proof panels, construction templates.

5. Machinery Manufacturing: Machine guard panels, gears, bearings.

6. Agricultural Applications: Greenhouse partitions, water tank linings.

Processing and Usage Recommendations

1. Processing Methods:

· Machinable (sawing, drilling, turning, milling).

· Thermoformable.

· Weldable (hot air welding, extrusion welding).

2. Usage Recommendations:

· Avoid prolonged exposure to high temperatures.

· Avoid contact with strong oxidizing agents.

· Allow for appropriate expansion gaps during installation.

3. Cleaning and Maintenance:

· Clean with mild detergents.

· Avoid strong acid or alkaline cleaners.

· Regularly inspect surface wear.

Black PE sheets are cost-effective, versatile engineering plastic panels with excellent chemical resistance, impact resistance, and weather resistance. Although they have limitations in temperature resistance and stiffness, selecting the appropriate type (HDPE or LDPE) and specifications can meet most industrial application needs. Their black appearance is not only aesthetically pleasing but also provides superior UV resistance, making them ideal for outdoor applications.