Productscpzx

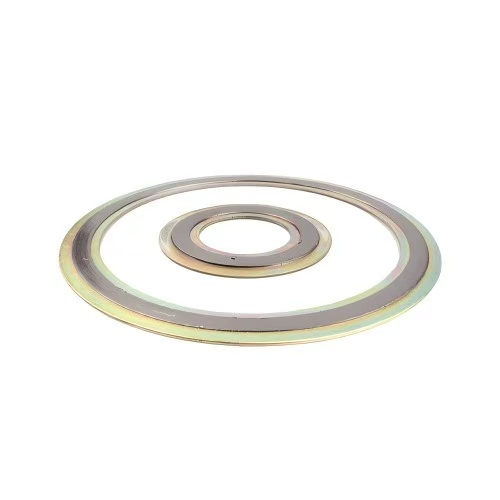

Introduction to Spiral Wound Gaskets

Spiral wound gaskets are sealing gaskets formed by alternately winding metal strips and non-metallic filler strips. They combine the strength of metal with the sealing properties of non-metallic materials, making them high-performance sealing components widely used in industrial pipelines and equipment.

Core Characteristics

| Characteristic | Description | Advantages |

| Excellent Sealing Performance | Multiple sealing barriers with metal and non-metal material combination | Suitable for high-temperature and high-pressure conditions |

| Good Elastic Compensation | Wound structure allows compression and rebound | Adapts to uneven flange surfaces |

| High Temperature and Pressure Resistance | Maximum operating temperature up to 800°C, pressure up to 25MPa | Suitable for harsh working conditions |

| Resistance to Creep and Relaxation | Metal strips provide mechanical strength and resist sustained loads | Maintains long-term sealing stability |

| Multiple Material Combinations | Metal and filler materials can be selected based on the medium | Adapts to various corrosive environments |

Basic Structure

| Component | Material Options | Function |

| Metal Strip | 304/316 stainless steel, Inconel, titanium alloy, etc | Provides mechanical strength and elasticity |

| Filler Material | Graphite, PTFE, ceramic fiber, etc. | Provides primary sealing function |

| Inner and Outer Rings | Usually same material as metal strip | Positioning and reinforcement |

Type Classification

| Type | Structural Features | Applicable Standards | Applications |

| Basic Type | No inner or outer rings | ASME B16.20 | Tongue-and-groove flange faces |

| Inner Ring Type | With inner ring | EN 1092-1 | Raised face flanges |

| Outer Ring Type | Outer Ring Type | DIN 2696 | Flat face flanges |

| Inner and Outer Ring Type | With both inner and outer rings | JB/T 90 | High-pressure applications |

Performance Parameters Table

| Performance Indicator | Graphite Filler | PTFE Filler | Ceramic Fiber Filler | Test Standard |

| Operating Temperature (°C) | -200~800 | -200~260 | -200~1100 | ASTM F38 |

| Operating Pressure (MPa) | ≤25 | ≤10 | ≤20 | ASME B16.20 |

| Compression Rate (%) | 18~30 | 15~25 | 20~35 | ASTM F36 |

| Recovery Rate (%) | ≥17 | ≥15 | ≥20 | ASTM F36 |

| Stress Relaxation Rate (%) | ≤15 | ≤20 | ≤18 | ASTM F38 |

Selection Guide

1. Material Selection Principles:

· Metal strip material should be equal to or better than flange material

· Filler material must be compatible with process medium

· Consider temperature and pressure fluctuations

2. Size Determination:

· Determine gasket size according to flange standards

· Consider bolt load and flange stiffness

· Reserve appropriate compression space

3. Special Condition Considerations:

· Use more elastic materials for thermal cycling conditions

· Use advanced alloy materials for corrosive environments

· Special treatment required for ultra-high vacuum environments

Installation and Usage Requirements

1. Pre-Installation Inspection:

· Flange sealing surfaces should be clean and undamaged

· Confirm correct gasket model and materials

· Check if gasket is intact and undamaged

2. Installation Specifications:

· Use positioning tools to ensure alignment

· Tighten bolts gradually in diagonal sequence

· Achieve specified bolt preload

3. Maintenance Recommendations:

· Regularly check bolt tightness

· Re-tighten after thermal cycling

· Inspect gasket compression status during shutdown

Application Fields

1. Petrochemical Industry: Reactors, heat exchangers, pipeline flanges

2. Power Industry: Steam turbines, boiler systems

3. Refining Units: Hydrocracking, catalytic cracking units

4. Nuclear Power Industry: Nuclear-grade equipment sealing

5. Aerospace: Engine pipeline systems

Spiral wound gaskets, with their unique structure and excellent sealing performance, are the preferred sealing elements for high-temperature and high-pressure conditions. Through reasonable material selection and correct installation, they can provide reliable long-term sealing for various industrial equipment. Their flexibility in multi-material combinations allows them to adapt to extreme conditions ranging from cryogenic to high-temperature and high-pressure environments.