Productscpzx

Features:

It is applicable to PTFE, vinylidene fluoride PVDF, polypropylene PPH, PVC, chlorinated polyvinyl chloride CPVC, cast iron, ductile iron,glass fiber reinforced plastics and other pipeline systems, and widely used in steel, metallurgy, petroleum, chemical, semiconductor, polysilicon, organic silicon, chemical fertilizer, dye, pharmacy, power, environmental sewage treatment and other industries.

Introduction to PTFE+EPDM Gaskets

PTFE+EPDM gaskets are composite sealing materials that combine the chemical inertness and low friction characteristics of polytetrafluoroethylene (PTFE) with the elasticity and compression resilience of ethylene propylene diene monomer (EPDM) rubber. These gaskets are widely used in industrial applications requiring both chemical corrosion resistance and excellent sealing performance.

Core Characteristics

| Characteristic | Description | Advantages |

| Excellent Chemical Stability | PTFE layer provides resistance to strong acids, alkalis, and solvents. | Suitable for extreme chemical environments. |

| Good Elastic Recovery | EPDM layer offers excellent compression resilience and sealing performance. | Adapts to uneven flange surfaces, ensuring long-term sealing. |

| Wide Temperature Range | -50°C to 150°C (short-term up to 200°C). | Suitable for most industrial temperature environments. |

| Aging Resistance | EPDM provides excellent ozone and weather resistance. | Extends service life and reduces maintenance needs. |

| Low Permeability | PTFE layer offers exceptional anti-permeability. | Prevents medium leakage and contamination |

Structural Types

| Type | Structural Features | Applications |

| Encapsulated Type | PTFE shell fully encloses EPDM core. | Highly corrosive media, zero-permeability applications. |

| Composite Type | Layered combination of PTFE and EPDM. | Applications requiring both sealing and chemical resistance. |

| Reinforced Type | Enhanced with glass fiber or metal skeleton. | High-pressure and high-temperature conditions requiring higher mechanical strength |

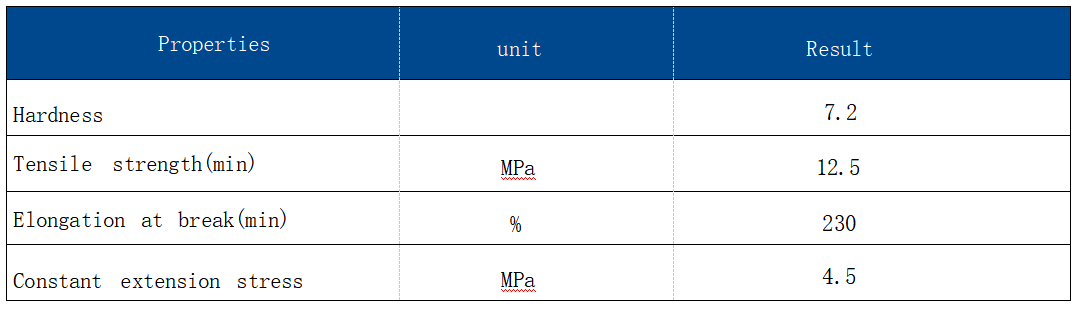

Performance Parameters Table

| Performance Indicator | Typical Value | Test Standard |

| Compression Rate | 15-25% | ASTM F36 |

| Recovery Rate | ≥50% | ASTM F36 |

| Tensile Strength | ≥8 MPa | ASTM D412 |

| Operating Temperature | -50°C to 150°C | - |

| Chemical Resistance | Resistant to most chemical media | ASTM D471 |

| Permeability | ≤10?1? m2/s | ASTM E96 |

Application Fields

1. Chemical Equipment: Reactors, storage tanks, pipeline flange sealing.

2. Pharmaceutical Industry: Clean pipeline systems, bioreactors.

3. Food Processing: Food-grade equipment sealing, compliant with FDA standards.

4. Semiconductor Manufacturing: High-purity chemical delivery systems.

5. Water Treatment: Sewage treatment equipment, drinking water systems.

6. Energy Industry: Oil refining equipment, liquefied gas storage systems.

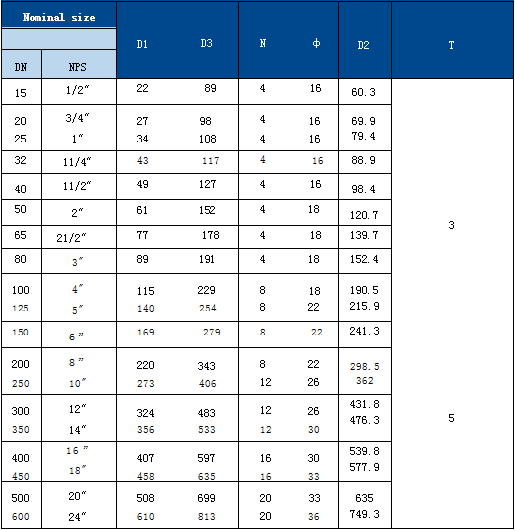

Selection and Installation Guide

1. Selection Considerations:

· Chemical properties of the medium.

· Operating temperature and pressure.

· Flange type and surface condition.

· Regulatory requirements (e.g., FDA, USP Class VI).

2. Installation Requirements:

· Flange surfaces should be clean and flat.

· Use a torque wrench and tighten in a crisscross sequence.

· Control compression within 25-30%.

· Avoid over-compression to prevent PTFE layer rupture.

3. Maintenance Recommendations:

· Regularly inspect compression status.

· Periodic replacement recommended under extreme conditions.

· Store away from direct sunlight and ozone-rich environments.

PTFE+EPDM gaskets achieve a perfect balance between chemical resistance and elastic sealing through clever material combination. Their unique composite structure retains the chemical inertness of PTFE while incorporating the excellent elasticity of EPDM, making them an ideal sealing solution for industries such as chemicals, pharmaceuticals, and food processing. Proper selection and installation are key to ensuring optimal performance.