Productscpzx

Features:

Because of its high corrosion resistance, stable physical properties, high temperature, the achievements of its good sealing performance, in the petroleum, chemical, pharmaceutical, power, steel industry has a wide range of applications. Suitable media include water, oil, acid solution, alkaline solution and almost any chemical ingredients.

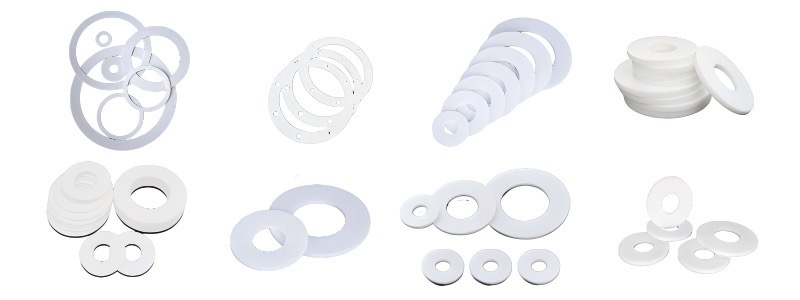

Introduction to PTFE Gaskets

PTFE gaskets are sealing gaskets made primarily from polytetrafluoroethylene (PTFE). They offer excellent chemical stability, temperature resistance, and low friction characteristics, making them an ideal sealing solution for demanding working conditions.

Core Characteristics

| Characteristic | Description | Advantages |

| Excellent Chemical Inertness | Resistant to all strong acids, alkalis, and organic solvents | Suitable for extreme chemical environments |

| Wide Temperature Range | Continuous use from -200°C to +260°C | Ideal for alternating high and low-temperature conditions |

| Extremely Low Friction Coefficient | Dynamic friction coefficient of only 0.04-0.07 | Suitable for frequently disassembled applications |

| Non-Stick Properties | Very low surface energy, does not adhere to any substance | Easy to clean, excellent anti-fouling properties |

| Excellent Electrical Insulation | Dielectric strength up to 100-200 kV/mm | Suitable for electrical insulation applications |

Manufacturing Processes

Process Type

Characteristics

Applicable Products

Compression Molding

High dimensional accuracy, good density

Standard specification gaskets

Machining

Flexible processing, can produce large-size gaskets

Custom non-standard gaskets

Extrusion Molding

High production efficiency, low cost

Pipe and rod gaskets

Performance Parameters Table

| Performance Indicator | Value Range | Test Standard |

| Density (g/cm3) | 2.1-2.3 | ASTM D792 |

| Tensile Strength (MPa) | 20-40 | ASTM D638 |

| Elongation at Break (%) | 200-400 | ASTM D638 |

| Compression Rate (%) | 5-15 | ASTM F36 |

| Recovery Rate (%) | Recovery Rate (%) | ASTM F36 |

Type Classification

| Type | Structural Features | Applications |

| Pure PTFE Gaskets | 100% | polytetrafluoroethylene Sealing strongly corrosive media |

| Filled PTFE Gaskets | Filled PTFE Gaskets | Improved wear and thermal conductivity |

| Expanded PTFE Gaskets | Microporous structure, soft and compressible | Irregular sealing surfaces |

| Composite PTFE Gaskets | Combined with other materials | Special performance requirements |

Selection Guide

1. Working Condition Analysis:

· Chemical properties of the medium

· Temperature and pressure range

· Sealing surface condition

2. Material Selection:

· Use pure PTFE for strongly corrosive environments

· Use filled PTFE for wear resistance requirements

· Use expanded PTFE for irregular sealing surfaces

3. Size Determination:

· Select according to flange standards

· Consider bolt load

· Reserve appropriate compression amount

Installation and Usage Requirements

1. Pre-Installation Inspection:

· Confirm gasket specifications and materials

· Check sealing surface finish (Ra ≤ 3.2 μm)

· Remove impurities from sealing surfaces

2. Installation Specifications:

· Use a torque wrench

· Tighten in diagonal sequence

· Control compression amount (20-30%)

3. Usage Precautions:

· Avoid over-compression

· Regularly check tightness status

· Note the effects of temperature changes

Application Fields

1. Chemical Equipment: Reactors, storage tanks, pipeline flanges

2. Pharmaceutical Industry: Clean pipeline systems, bioreactors

3. Food Processing: Food-grade equipment sealing

4. Electronics and Electrical: High-purity chemical delivery systems

5. Aerospace: Fuel systems, hydraulic systems

Special Treatments

1. Reinforcement Treatments:

· Glass fiber reinforcement

· Carbon fiber reinforcement

· Bronze filled reinforcement

2. Modification Treatments:

· Improved creep resistance

· Enhanced wear resistance

· Improved thermal conductivity

3. Surface Treatments:

· Surface activation treatment

· Anti-stick treatment

· Conductive treatment

PTFE gaskets, with their unique chemical inertness, wide temperature adaptation range, and excellent dielectric properties, are the preferred sealing material for strongly corrosive working conditions. Although they have limitations such as cold flow and poor wear resistance, reasonable structural design and correct usage methods can fully leverage their performance advantages, providing reliable sealing solutions for industries such as chemicals, pharmaceuticals, and food processing.