Productscpzx

Features:

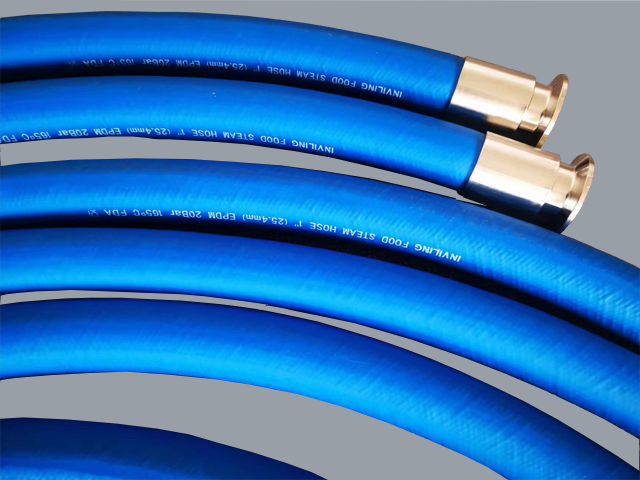

Special transparent inner lining,

free of plasticisers Reinforcements: synthetic fibres Blue, fabric patterned NBR-cover, resistant to ozone, weather, UV, oils, fats and abrasion

Working pressure up to 20 bar / 290 psi

Temperature resistance from -30°C to +90°C / -22°F to +194°F

Can be steamed up to +130°C / +266°F (max. 30 minutes)

Absolutely neutral to taste and odour

Highly flexible, can be overrun

FDA Certificate

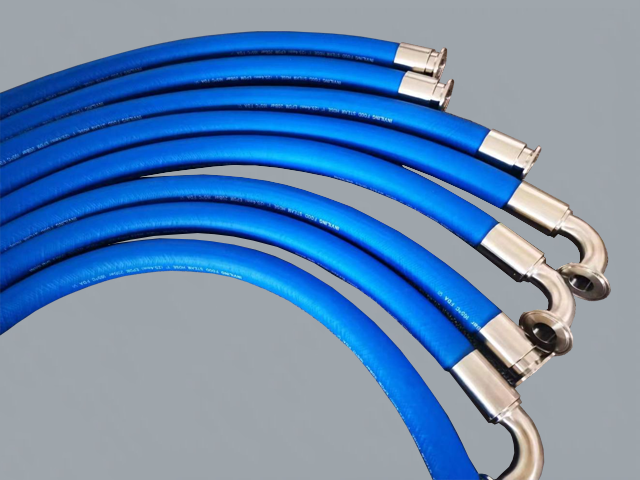

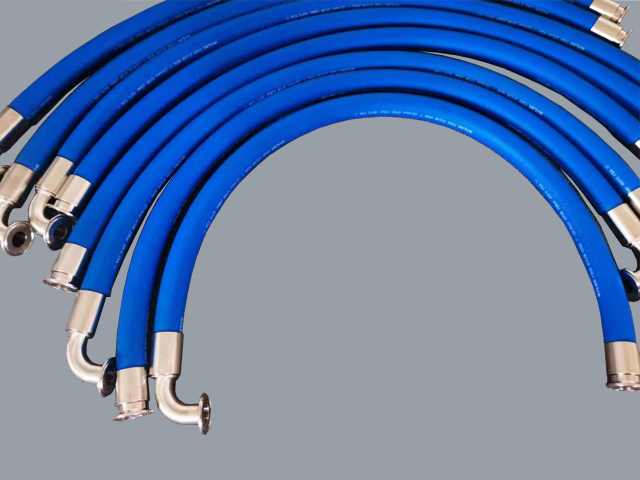

Product display:

Introduction to Polytetrafluoroethylene (PTFE) Drinking Water Pipes

Polytetrafluoroethylene (PTFE) drinking water pipes are pipelines made from 100% pure PTFE resin, specifically designed for transporting drinking water, high-purity water, and liquid food. They are not ordinary household pipes but rather special-grade tubing used in high-end applications where water purity, safety, and corrosion resistance are critically important.

Due to the exceptional properties of PTFE (commonly known as "Teflon" or the "King of Plastics"), PTFE drinking water pipes offer unparalleled performance and safety assurance.

Core Characteristics (Why Choose PTFE for Drinking Water Pipes?)

| Characteristic | Description | Significance for Water Systems |

| Absolute Inertness & Safety | Made from 100% pure PTFE with no additives (e.g., plasticizers). Complies with stringent certifications such as FDA, USP Class VI, and 3-A Dairy. | Ensures water quality remains uncontaminated by the pipeline material, with no leaching, pure taste, and absolute non-toxicity. |

| Exceptional Chemical Stability | Resists all chemicals involved in drinking water treatment, such as chlorine, ozone, and fluorides. Its corrosion resistance far surpasses stainless steel. | The pipe itself won’t corrode from disinfectants in water, preventing metal ion leaching or rust contamination, maintaining long-term water purity. |

| Ultra-Smooth Non-Stick Inner Wall | Extremely low surface friction coefficient, smooth and non-adhesive. | Scale and bacteria resistant: Microorganisms and minerals struggle to adhere, effectively preventing biofilm formation and significantly reducing secondary contamination risks. Low fluid resistance. |

| High and Low-Temperature Adaptability | Operates reliably in extreme temperatures from -190°C to +260°C. | Withstands high-temperature sterilization (e.g., SIP, steam above 121°C) and remains functional in freezing conditions without becoming brittle. |

| Long Lifespan & Durability | Highly resistant to aging and weathering, with a service life far exceeding ordinary plastic pipes. | Once installed, requires minimal maintenance, potentially offering lower total cost of ownership over its lifecycle |

Typical Applications

Due to their high cost, PTFE drinking water pipes are typically not used in ordinary residential plumbing but are instead focused on the following high-end fields:

1. Premium Drinking Water Systems: Used as the final distribution piping in point-of-use drinking water systems for high-end hotels, villas, and hospitals, ensuring consistent water quality from purification equipment to the tap.

2. Food and Beverage Industry: Transporting ingredients in production lines for beer, beverages, dairy, soy sauce, vinegar, etc., particularly in processes requiring CIP (Clean-in-Place) or SIP (Sterilize-in-Place).

3. Pharmaceutical and Bioengineering:

· Pharmaceutical Water Systems: The preferred material for final distribution pipelines carrying Water for Injection (WFI) and Purified Water (PW), meeting GMP standards.

· Bioreactors and Culture Media Transfer: Used in cell culture and fermentation processes requiring extreme cleanliness and no leachables.

4. Laboratories and High-Purity Analysis: Transfer tubing for laboratory ultrapure water systems, avoiding metal ion leaching that could affect experimental accuracy.

Important Considerations

· Higher Cost: The raw material and processing costs of PTFE pipes are significantly higher than common materials like PPR or stainless steel, which is their main drawback.

· Pressure Resistance and Rigidity: Pure PTFE is relatively soft, and its pressure rating is generally lower than stainless steel pipes. For higher-pressure systems, thick-walled pipes or PTFE-lined stainless steel composite pipes are used. The latter combines a stainless steel outer shell for pressure resistance with a PTFE liner for purity, offering the best of both materials.

· High Installation Requirements: Connection requires specialized PTFE flanges or PFA (Perfluoroalkoxy) welding techniques. Installers must be professionally trained to ensure flat, sealed, and contamination-free joints, which is critical for system integrity.

· Visual Monitoring: The semi-transparent nature allows for some observation of the fluid inside the pipe.

Polytetrafluoroethylene (PTFE) drinking water pipes represent the highest standard in drinking water transportation materials. They sacrifice cost-effectiveness for unparalleled safety, purity, and durability. For applications where water quality is the top priority—especially in pharmaceuticals, high-end food and beverage, and precision industries—PTFE pipes are often the irreplaceable ultimate choice, serving as the gold standard for ensuring water safety in the "last mile" of distribution.