Productscpzx

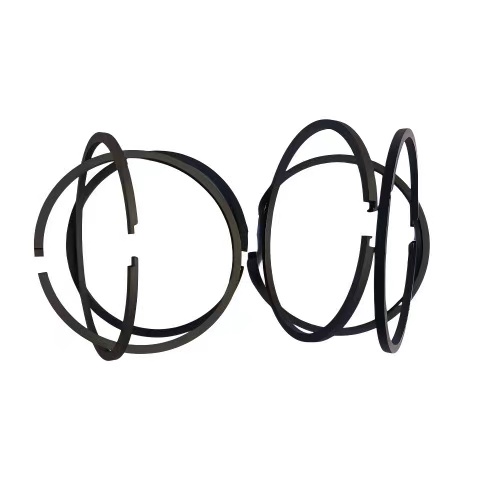

Introduction to Piston Rings

Piston rings are metal elastic rings installed in piston grooves, used to seal the combustion chamber, regulate oil, and control heat transfer. They are one of the core components of internal combustion engines.

Core Functions

| Function | Description | Importance |

| Sealing the Combustion Chamber | Prevents gas leakage into the crankcase | Prevents gas leakage into the crankcase |

| Oil Control | Scrapes excess oil from cylinder walls, forming an oil film | Scrapes excess oil from cylinder walls, forming an oil film |

| Heat Transfer | Conducts piston heat to the cylinder walls | Prevents piston overheating and damage |

| Support and Stability | Reduces impact between piston and cylinder walls | Reduces impact between piston and cylinder walls |

Material Types

| Material Type | Characteristics | Applicable Engines |

| Gray Cast Iron | Low cost, good self-lubrication | Standard gasoline and diesel engines |

| Ductile Cast Iron | High strength, good wear resistance | Heavy-duty diesel engines |

| Steel Rings | High strength, fatigue resistance | High-performance engines |

| Coated Rings | Special surface treatment, reduced friction and wear | Modern high-efficiency engines |

Piston Ring Types

| Type | Installation Position | Main Function | Characteristics |

| Compression Rings | Upper ring groove | Seal combustion gases | Withstand high temperature and pressure |

| Oil Rings | Lower ring groove | Control oil | Designed with oil return holes |

| Combination Rings | Middle ring groove | Combined sealing and oil control | Multi-functional design |

Performance Parameters Table

| Performance Indicator | Compression Rings | Oil Rings | Oil Rings |

| Radial Pressure (MPa) | 0.1-0.3 | 0.3-0.8 | ISO 6621 |

| End Gap (mm) | 0.2-0.5 | 0.1-0.3 | ISO 6624 |

| Hardness (HV) | 200-400 | 300-500 | ISO 6507 |

| ISO 6507 | 100-150 | 120-180 | ISO 6892 |

Design Requirements

1. Sealing Requirements:

· Ensure appropriate radial pressure

· Control end gap

· Ensure proper ring and groove fit

2. Wear Resistance Design:

· Surface treatment (chromium plating, molybdenum spraying, etc.)

· Material selection

· Structural optimization

3. Thermal Management:

· Heat conduction path design

· Thermal expansion compensation

· Thermal stress control

Installation Precautions

1. Pre-Installation Inspection:

· Check groove cleanliness

· Measure ring end gap

· Confirm ring installation sequence

2. Installation Tools:

· Use dedicated piston ring expander

· Avoid over-expansion

· Prevent ring deformation

3. Installation Key Points:

· Install in correct sequence

· Stagger ring end gaps

· Ensure rings can rotate freely

Common Failure Modes

1. Wear Failure:

· Normal wear

· Abnormal wear (abrasive wear, corrosive wear)

2. Fracture Failure:

· Fatigue fracture

· Overload fracture

3. Sticking Failure:

· Carbon deposit sticking

· Overheating sticking

Maintenance

1. Regular Inspection:

· Check compression pressure

· Observe exhaust smoke color

· Monitor oil consumption

2. Replacement Standards:

· End gap exceeds limits

· Loss of elasticity

· Severe wear

3. Usage Recommendations:

· Use appropriate specification oil

· Avoid engine overheating

· Regularly replace air filters

As key components of engines, piston rings directly affect engine power, efficiency, and service life. Through reasonable design, correct installation, and proper maintenance, piston rings can perform optimally and extend engine service life.