Productscpzx

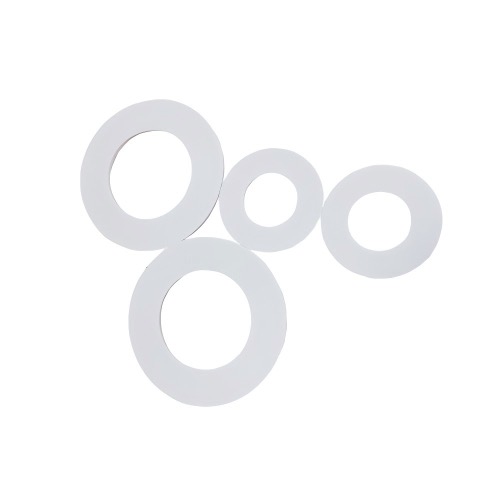

Introduction to Fiberglass Gaskets

Fiberglass gaskets are sealing gaskets made primarily from glass fiber as the reinforcing material, compounded with a resin matrix. They offer excellent high-temperature resistance, corrosion resistance, and mechanical strength, making them an ideal sealing solution for medium to high-temperature working conditions.

Core Characteristics

| Characteristic | Description | Advantages |

| Excellent High-Temperature Resistance | Long-term service temperature up to 550°C | Suitable for medium to high-temperature conditions |

| Good Corrosion Resistance | Resistant to most acids, alkalis, and organic solvents | Suitable for corrosive media |

| High Mechanical Strength | Excellent compressive and tensile properties | Can withstand high sealing pressures |

| Low Thermal Conductivity | Low thermal conductivity, good insulation performance | Suitable for high-temperature equipment sealing |

| Good Insulation Properties | Excellent electrical insulation performance | Suitable for electrical equipment sealing |

Material Composition

| Component | Material Type | Function |

| Function | Alkali-free glass fiber cloth | Provides mechanical strength and temperature resistance |

| Matrix Material | Silicone rubber, fluoroelastomer, etc. | Provides sealing and flexibility |

| Filler Material | Graphite, mica, etc. | Improves temperature resistance or sealing performance |

Performance Parameters Table

| Performance Indicator | Silicone Fiberglass Gasket | Fluoroelastomer Fiberglass Gasket | Test Standard |

| Operating Temperature (°C) | -60~300 | -20~400 | ASTM D2000 |

| Tensile Strength (MPa) | ≥20 | ≥25 | ASTM D638 |

| Compression Rate (%) | 10~20 | 8~15 | ASTM F36 |

| Recovery Rate (%) | ≥40 | ≥35 | ASTM F36 |

| Density (g/cm3) | 1.8~2.2 | 2.0~2.5 | ASTM D792 |

Type Classification

| Type | Structural Features | Applications |

| Full Fiberglass Type | Pure glass fiber material | High-temperature insulation sealing |

| Rubber Composite Type | Fiberglass and rubber composite | Sealing requiring elasticity |

| Graphite Composite Type | Fiberglass and graphite composite | High-temperature and high-pressure sealing |

| Metal Reinforced Type | Fiberglass and metal composite | Ultra-high strength sealing |

Selection Guide

1. Working Condition Analysis:

· Operating temperature and pressure

· Media corrosiveness

· Sealing requirement level

2. Material Selection:

· Use silicone-based for medium-temperature environments

· Use fluoroelastomer-based for high-temperature environments

· Use special resins for specific media

3. Size Determination:

· Select according to flange standards

· Consider thermal expansion factors

· Reserve appropriate compression amount

Installation and Usage Requirements

1. Pre-Installation Preparation:

· Check sealing surface finish (Ra ≤ 3.2 μm)

· Remove impurities from sealing surfaces

· Measure flange parallelism

2. Installation Specifications:

· Use a torque wrench

· Tighten in diagonal sequence

· Control compression amount (15-25%)

3. Usage Precautions:

· Avoid impact and vibration

· Regularly check tightness status

· Note the effects of sudden temperature changes

Application Fields

1. Petrochemical Industry: Reactors, cracking furnaces, high-temperature pipelines

2. Power Equipment: Steam turbines, boilers, heat exchangers

3. Aerospace: Engines, combustion chamber sealing

4. Automotive Industry: Exhaust systems, turbochargers

5. Industrial Furnaces: Heat treatment equipment, smelting furnaces

Special Treatments

1. Surface Treatments:

· Graphite coating treatment

· PTFE impregnation treatment

· Anti-stick treatment

2. Reinforcement Treatments:

· Metal mesh reinforcement

· Carbon fiber reinforcement

· Ceramic fiber reinforcement

3. Modification Treatments:

· Improve flexibility

· Enhance sealing performance

· Increase corrosion resistance

Fiberglass gaskets, with their excellent temperature resistance, corrosion resistance, and mechanical strength, are important sealing materials for medium to high-temperature working conditions. Through proper material selection and correct installation, they can provide reliable sealing protection for industries such as petrochemicals and power equipment. Understanding their characteristics and selecting the right type is key to ensuring sealing effectiveness.